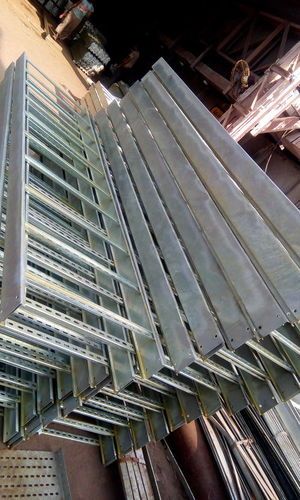

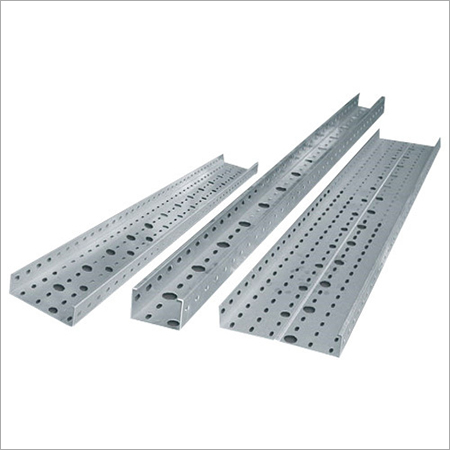

Perforated Cable Trays

Product Details:

- Max. Working Load Up to 75 kg/m

- Surface Finish GI Galvanized

- Conductor Material Aluminum

- Deflection Within 1/250 of span under max load

- Product Type Cable Tray

- Material Stainless Steel

- Standard Thickness 1.2 mm to 3 mm

- Click to view more

Perforated Cable Trays Price And Quantity

- 10 , , Piece

- 200 INR/Piece

Perforated Cable Trays Product Specifications

- 1.2 mm to 3 mm

- GI Galvanized

- Aluminum

- 50 mm to 1000 mm

- Silver

- Within 1/250 of span under max load

- 2500 mm or customized

- Varies based on dimensions and material

- 25 mm to 150 mm

- Customizable as per requirement

- Cable Tray

- Up to 75 kg/m

- Stainless Steel

Perforated Cable Trays Trade Information

- 200 , , Piece Per Day

- 1 Week

Product Description

Perforated Cable Trays are provided with up to 3 meters of height. These are suitable for power distribution as well as communication. Made of mild steel, these trays of 3-5 mm thickness are demanded in different sectors. These products have holes on their bottom sheet and are used to giving power to the signal cables. In a way, these products assist in distributing the electricity in industrial plants, gyms, hospitals, department stores, airports and many others.

Power Cable Trays Specifications

|

Length |

Upto 3 meter |

|

Usage/Application |

Power Distribution and Communication |

|

Technique |

Hot Rolled |

|

Brand |

J.K Poles |

|

Material |

Mild Steel |

|

Thickness |

3-5 mm |

Frequently Asked Questions

Why perforated cable tray is used?

Excellent ventilation is provided by perforated cable trays, which also lengthens the life of cables and may be fixed to any kind of building. A cable tray system, according to the NEC, is a unit or assembly of units or sections with related fittings that forms a structural system used to safely anchor or support cables and raceways.

What perforated cable tray?

Ferrotech Perforated Cable Trays are a type of cable tray with holes on the bottom sheet and side rails for installing power and signal cables to distribute electricity, signalling in commercial buildings such as department shops, gyms, hospitals, and airports.

Where are perforated cable trays used?

Cable trays serve as mechanical supports and protect installed wires in any significant wiring job. When there is a numerous wire configuration for power and signal cables, cable trays are typically used. The wires may overheat under strong loads, especially if the cabling system is enclosed.

What is the benefit of cable tray?

Because they provide a neater, cleaner appearance, cable trays are preferable to traditional wire installations. Although several cables may be required to run various systems, you are not required to see every size and colour variant.

Versatile Installation Options

Perforated Cable Trays are designed to be adaptable in diverse environments. They support multiple installation methods, including wall-mounted, floor-mounted, and suspended configurations, ensuring optimal cable organization in industrial and commercial spaces. This flexibility allows for tailored solutions to suit specific site requirements and cable routing challenges.

Superior Corrosion and Temperature Resistance

The trays boast a galvanized surface finish, offering high resistance to corrosion, even in demanding or outdoor settings. Engineered from stainless steel, they reliably operate within a temperature range of -40C to +120C, making them suitable for facilities exposed to extreme thermal conditions or fluctuating climates.

FAQs of Perforated Cable Trays:

Q: How are perforated cable trays installed in industrial settings?

A: Perforated cable trays can be installed using wall-mounted, floor-mounted, or suspended methods. The choice depends on site layout, cable routing needs, and accessibility. Standard accessories such as couplers, bends, tees, elbows, and covers are used to ensure secure and seamless connections during installation.Q: What advantages does the galvanized finish provide for cable management in harsh environments?

A: The galvanized (GI) surface finish gives these cable trays high corrosion resistance, protecting them from moisture, chemicals, and other corrosive agents. This ensures long-lasting performance and reduced maintenance costs in challenging industrial and commercial settings.Q: When should I choose perforated cable trays over solid cable trays?

A: Perforated cable trays are ideal when ventilation and heat dissipation are necessary, such as in installations with power and data cables. Their perforations help prevent overheating and allow dust and debris to escape, making them suitable for high-density cable environments.Q: Where can perforated cable trays be installed for optimal cable organization?

A: They can be installed in factories, offices, commercial buildings, and facilities requiring organized cable management. Wall, floor, or suspended installations accommodate various architectural layouts, optimizing space usage and enhancing safety.Q: What is the process for selecting compatible accessories for perforated cable trays?

A: Accessories like couplers, bends, tees, elbows, and covers should be chosen based on tray layout and cable routing design. This approach ensures all necessary directional changes and branch connections are securely integrated, complying with ISI, IEC, and NEMA standards.Q: How does using smooth, deburred edges benefit cable installation and maintenance?

A: Smooth and deburred edge design considerably reduces the risk of cable damage and safeguards installers from cuts or abrasions. This feature ensures safer handling and easier maintenance in busy industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Cable Tray' category

|

JK POLES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese